Interior componentsInterior parts

Since we started selling edge tapes in 1978, we have been manufacturing one-of-a-kind products with free-thinking and creative technology. Today, we hold the top market share in the edgebanding industry. Our products improve in design and functionality and provide people with conditions to function more comfortably and safely in their daily lives. We are engaged in a wide range of businesses through superior products that communicate a sense of beauty.

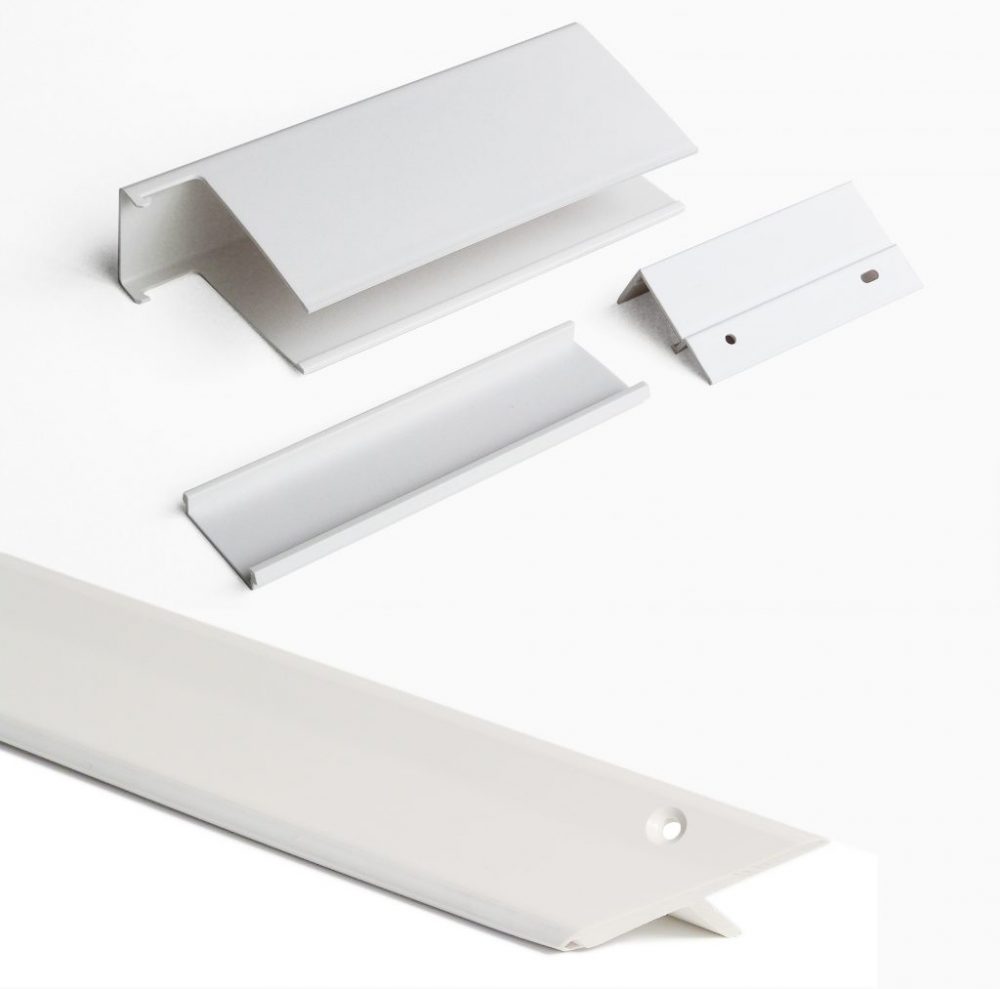

Custom ExtrusionsDeformed extrusion

We are engaged in the planning and development of plastic products of various shapes.

The extrusion process is a forming method in which resin is melted at a high temperature of about 200 degrees Celsius, pressurized and poured into a mold to form a cross-sectional shape as required. It has the advantage of being able to produce very complex cross-sections and having a very smooth surface that does not require finishing, but it does require a high level of technology and various kinds of know-how.

Our extrusion process can use a wide range of resins such as PVC, PS, ABS and PP, and two-layered and three-layer designs in which hardened, soft and foamed materials are combined to form a single product.

Supply Availability: We can also produce large extrusions of approximately 300 mm x 300 mm and endless products in long lengths and rolls.

Multilayered Extrusion (Two layered/ Three layered design)

Combining multiple resins of different hardness and colours, makes it possible to add functionality and design to the products, including cushioning and hinge functions. Also, it improves the accuracy and quality of the products by the integrated extrusion process, which reduces man-powers and leads to cost reductions.

Mating Products

This is a product in which two or more parts, such as a lid and base, are fitted.

We have designed our products with an image of movement in mind, how to combine resins and non-resin parts, and which parts should be open, bent, and fixed to make them easier to use.

We propose the type of resin and molding method in consideration of every possible aspect of your use.

Special coating and gravure printing

Panefri Industries also specializes in surface treatment and surface modification after the extrusion process.

We can offer various process methods, including special coatings such as clear coat, UV coat and primer. Also, colouring, wood grain printing and decorative sheeting processed by gravure printing are available.

We will propose your customize products.

We are continuously researching and developing not only extrusion techniques but also a variety of other resin molding methods.

「Can you do something like this? or Can you make a product like this? 」If you have any questions like this, please feel free to contact us.

We can offer the most suitable solutions to meet your needs, with our advanced techniques and know-how we have accumulated over the years.

Post processing

We also offer post-processing such as straight-cutting, notching, drilling and sealing. Our integrated service from the extrusion process to post-processing leads to shorter delivery times and reduced costs.

3D Fiber Products3D Fiber Products

We will propose various ideas using the new characteristic cushioning material.

We are participating in the Mie Life Innovation Promotion Project, sponsored by Mie Prefecture, which aims to create new value by introducing new technologies and ideas in medicine, health, and welfare, as well as creating innovative pharmaceuticals and medical devices and developing related industries. We are developing materials and products that are useful in the welfare industry.

Our original cushioning material, “Calfiber (3-Dimensional Reticular Structure),” was also developed to prevent bedsores, attracting attention in the medical and nursing care fields. It is breathable, cushioning, durable, and washable so that it can keep in clean. Because it is a material that can be used in medical and nursing care fields, you can use it in your daily lifestyle with confidence.

Hardware store productsHome improvement products

We have developed products for general consumers based on professional-use products that we have refined as construction materials.

We commercialize a wide range of products for the general public that features special processing and technologies for professional use, which we have developed in housing construction materials while networking with hardware stores and retailers nationwide.

We also offer a variety of convenient products, such as pre-glued edge tape and “Sliding door Low-friction tape,” improving slippage of shoji and fusuma, “Floor parting materials,” and curing material called “Repitak” for professional construction materials.

July 1st, 2017

We are pleased to announce the completion of our new DIY and interior materials catalog Vol. 1.

A PDF version is also available for your reference. (Please note that it may look different from the actual colour and texture in the monitor and printing environment.)

Download Catalogues

Environmental ScienceEnvironmental science

We develop and sell numerous “eco-friendly” products.

Panefri Industrial Co., Ltd. develops and sells a number of eco-friendly products with the aim of realizing a recycling-oriented society.

We contribute to the realization of a sustainable society by reducing environmental impacts, such as removing toxic substances and using renewable resources.

Various products are available, such as the Palmist series that compose household food waste, DUSKLEIN series that breaks down food waste without using electricity. Panicum miliaceum Amino, a 100% organic fertilizer that supports organic farming and pesticide-reducing cultivation, Morino-Megumi, a 100% bark compost, Kuruna Spray, a garden vegetable protection liquid, and Herbicide No.1 Plus, a herbicide with no chemically synthetic ingredients.

Institute of Environmental Science

Our laboratory aims to contribute to society by developing unique products and technologies focusing on the various functions of microorganisms and naturally occurring ingredients.

In particular, we focus on proposing new technologies that lead to solutions in a way that has the lowest possible environmental impact by identifying potential needs in the life science field, contributing to comfortable living, and in the agricultural and horticultural fields, which are responsible for the stable production of safe food.

A small group of elite researchers run our development operations, and we place great importance on the imaginative ideas of our unique researchers. Product planning developed by insights and inspirations is yield to more concrete themes through lively team discussions.

Only technologies that have passed the strict examination from the scientific, economical and practical aspects will be the final products.

Each researcher and employee is responsible for a wide range of duties,

from basic development to application, also including supporting development.